Why Aluminium Wiring Was Once Popular (And Why It’s a Problem Now)

Aluminium wiring was widely used in home electrical systems during the mid-20th century. When copper prices skyrocketed in the 1960s and 1970s, aluminium wiring became a cheaper alternative, finding its way into millions of American homes. At that time, it seemed like a practical decision, but now, many homeowners are facing serious issues related to aluminium wiring.

Understanding why aluminium wiring was popular back then and why it’s problematic now can help you make better choices about the safety and value of your property. If you live in or are considering buying a home built during this time period, it’s crucial to know the risks and benefits associated with aluminium wiring.

This article explains:

- The reasons behind the popularity of aluminium wiring

- The technical and safety challenges it poses today

- What current homeowners should be aware of

- Professional solutions for dealing with outdated or hazardous wiring systems

Being informed can help you protect your investment and keep your household safe.

Why Aluminium Wiring Became Popular in the 1960s and 1970s

During the mid-1960s to early 1970s, the price of copper surged significantly, creating a demand for more affordable alternatives. Homebuilders and electricians turned to aluminium wiring as a solution. As a result, nearly 2 million American homes were outfitted with aluminium wiring between 1965 and 1973.

Benefits of Aluminium Wiring

- Affordability: Compared to copper, aluminium was much cheaper. This cost-effectiveness made it an attractive option during a period when copper prices were prohibitively high.

- Availability: Copper shortages meant that aluminium was readily available. This ensured that construction projects could continue without delays.

- Weight: Aluminium is lighter than copper, making it easier to handle and install.

These initial benefits helped aluminium wiring gain popularity quickly among builders looking for efficient, cost-effective solutions during a time of economic challenge in the electrical industry.

Understanding the Material Properties of Aluminium Wiring

Understanding aluminium wire properties is crucial for grasping why these systems present unique challenges in modern homes. Two terms matter most: conductivity and thermal expansion.

1. Conductivity

Conductivity refers to how easily electricity flows through a material. Copper has higher conductivity than aluminium, meaning it carries electrical current more efficiently. When you substitute copper with aluminium, wires must be larger to handle the same load safely. Using thinner aluminium wiring can lead to overheating, which is a significant electrical safety risk.

2. Thermal Expansion

Thermal expansion describes how much a material expands or contracts as temperatures change. The thermal expansion of aluminium is significantly greater than that of copper—aluminium wires expand and contract more each time electricity heats them up or they cool down afterward. This repeated movement at connection points (such as outlets, switches, and junction boxes) can loosen screws and terminals over time.

3. Durability

Durability also comes into play. Aluminium is a softer metal compared to copper, making it more prone to nicks and breaks during installation or repairs.

These differences matter because poor conductivity of aluminium wiring and constant expansion/contraction both increase the risk of loose connections—one of the leading causes of electrical failures and potential fire hazards in homes wired with aluminium. Understanding these properties helps clarify why older wiring systems demand special attention from homeowners and professionals alike.

Safety Problems Associated with Aluminium Wiring Today

Loose connections top the list of electrical hazards aluminium wire brings to modern homes. As aluminium expands and contracts with each cycle of heating and cooling, connections inside outlets, switches, and junction boxes can become less secure. This movement creates tiny gaps where electricity meets resistance—a situation that leads to excessive heat buildup.

Increased resistance at these points is a major factor in the aluminium wiring fire risk. Over time, even a small loose connection can escalate into dangerous overheating. The result: insulation melts, wires degrade, and the chance of an electrical fire rises sharply.

Watch for several warning signs that signal trouble:

- Flickering or dimming lights

- Warm or discolored wall plates/outlets

- Buzzing or crackling sounds from switches or receptacles

- Circuit breakers that trip repeatedly without clear cause

These circuit breaker issues could be a sign of an overloaded circuit, which is another common problem with aluminium wiring. According to industry research, homes wired with pre-1972 aluminium wiring are about 55 times more likely to have “fire-hazardous” connections than those using copper. This staggering statistic highlights why aluminium wiring was once popular (and why it’s a problem now) for homeowners and insurers alike. Understanding these risks is essential for anyone living in or considering a home built during the era of widespread aluminium wiring installation.

Additional Issues Linked to Aluminium Wiring in Residential Homes

Corrosion at Connection Points

Corrosion is a significant issue with aluminium wiring due to its chemical properties. When aluminium wire connections are exposed to air, they form an oxide layer that can deteriorate over time. This corrosion reduces the quality of electrical contact, leading to higher resistance and potential overheating. Corroded connections are less reliable and can pose serious safety risks.

Device Compatibility Problems

Aluminium wiring presents compatibility challenges with modern electrical devices. Many switches and outlets are specifically designed for copper wiring, not aluminium. Using these incompatible devices with aluminium wires can cause loose connections and increase the risk of fires. Always check for UL-listed CO/ALR (Copper-Aluminum Revised) devices that are safe for use with aluminium wiring.

Impact on Home Resale Value and Insurance

Homes with aluminium wiring often face reduced resale value due to perceived safety risks. Potential buyers may be wary of the hazards associated with older wiring systems, affecting the marketability of your property. In some cases, like when putting an offer on a home that has aluminum wiring, this could lead to complications during the negotiation process. Additionally, securing home insurance can be challenging; many insurers either refuse coverage or impose higher premiums for homes with aluminium wiring due to the increased fire risk. It’s crucial to address these issues to maintain both the safety and value of your home.

If you’re facing these issues with aluminium wiring in your home, it may be time to seek professional help. Don’t hesitate to reach out to experts who can assist you in resolving these problems safely and effectively. You can contact us for further assistance.

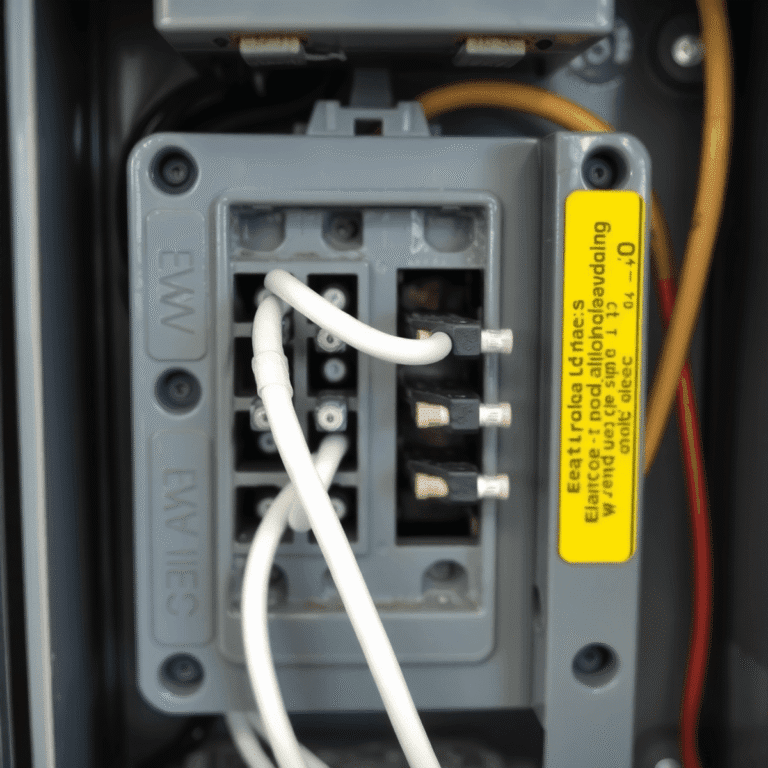

Inspection, Maintenance Considerations, And Solutions for Aluminium-Wired Homes

Regular aluminium wiring inspection is a non-negotiable step if your home was built or renovated between the mid-1960s and late 1970s. Certified electricians with specific experience in aluminium electrical systems are essential—not all electricians are trained to spot the subtle red flags unique to these installations. Protek Electrical and Data, for example, brings over 15 years of expertise to every job and prioritizes safety during all inspections and repairs.

Key Maintenance Tasks for Aluminium Wiring

Catching issues early can make a significant difference in safety:

- Outlet Temperature Checks: Routinely touch outlets and switch plates. If they feel warm or hot, this could signal overheating—a major risk factor for electrical fires.

- Visual Inspections: Look for discoloration around outlets and switches, as well as signs of melting, scorching, or unusual odor.

- Listen for Unusual Sounds: Buzzing or crackling near outlets may indicate loose connections or arcing.

- Frequent Breaker Trips: Take note if your breakers trip often without obvious cause. This may point to underlying issues with aluminium wiring.

Scheduled maintenance by a professional helps ensure these checks are thorough and conducted safely.

Fixing Aluminum Wiring: Permanent and Practical Solutions

Complete Rewiring with Copper

This is the gold standard—removing all aluminium wiring and replacing it with copper. It eliminates compatibility risks and addresses every connection point. The downside is cost; rewiring an entire house requires significant investment in both labor and materials.

Pigtail Connections Using Special Connectors

A more practical solution involves using pigtail connections where short lengths of copper wire are joined to existing aluminium wire at receptacles, switches, and fixtures. Special connectors like COPALUM—approved by authorities such as UL—create a safe bond that reduces fire hazards from loose or corroded connections. Not all connectors are equal; only those specifically rated for aluminium-to-copper transitions should be used.

Routine inspection and proactive maintenance give homeowners peace of mind while bridging the gap between outdated materials and modern safety standards. These steps set the stage for long-term electrical safety upgrades handled by certified professionals.

The Importance of Hiring Professional Electricians for Aluminium Wiring

Hiring a professional electrician who specializes in aluminium wiring is essential for maintaining the safety and durability of your home’s electrical system. Certified experts, such as those at Protek Electrical and Data, have the necessary skills and knowledge to effectively address the specific challenges posed by aluminium wiring.

Services Provided by Professional Electricians

Here are some key services offered by professional electricians:

- Inspections: Regular inspections are crucial for identifying potential problems early on. Licensed electricians in Melbourne, skilled in aluminium repairs, can conduct thorough evaluations of your electrical system, checking for signs of wear, corrosion, or loose connections.

- Upgrades: Upgrading components like switchboards is vital for maintaining a safe electrical network. Protek Electrical and Data offers customized upgrade services tailored to homes with older wiring systems. This includes installing modern, compatible hardware that can better handle the specific properties of aluminium wiring.

- Repairs: Effective repair services are necessary to address any existing issues promptly. Certified professionals can fix problems such as overheating wires or faulty connections using techniques designed to mitigate the risks associated with aluminium wiring.

- Maintenance: Ongoing maintenance is key to preventing future problems. This involves routine tasks like visual inspections and temperature checks of outlets and switches, ensuring that any issues are caught before they escalate into more significant safety hazards.

Why Expertise is Important

Certified electricians from reputable companies like Protek Electrical and Data bring over 15 years of experience in installations, repairs, upgrades, and maintenance of electrical systems. Their high standards of service, combined with their commitment to safety and customer satisfaction, make them an excellent choice for managing the risks associated with aluminium wiring in residential homes.

By regularly engaging with professional electrical services, you can ensure that your home remains safe and compliant with current electrical standards.

Conclusion

Understanding the history and risks of aluminium wiring is essential for every homeowner. While aluminium gained popularity in the 1960s and 1970s for its affordability and availability, today it presents significant safety concerns that cannot be ignored. Regular inspections by licensed professionals are your best line of defense against potential fire hazards.

Electrical safety tips for aluminum wire homes:

- Schedule routine checks with certified electricians experienced in aluminium wiring.

- Upgrade outlets, switches, and panels as needed to meet modern safety standards.

- Consider safe rewiring solutions or approved connector methods like COPALUM pigtails.

Protecting your property and loved ones starts with proactive action. If you suspect your home contains aluminium wiring, reach out to a trusted provider such as Protek Electrical and Data for expert assessment and tailored upgrade options.

For a quick aluminium wiring summary: what was once a cost-saving solution now requires vigilance and modern solutions to ensure lasting safety—making it vital for homeowners to stay informed about Why Aluminium Wiring Was Once Popular (And Why It’s a Problem Now).

FAQs (Frequently Asked Questions)

Why was aluminium wiring popular in American homes during the 1960s and 1970s?

Aluminium wiring became popular between 1965 and 1973 due to a surge in copper prices, making aluminium a cost-effective and readily available alternative for nearly 2 million American homes during copper shortages.

What are the key material properties of aluminium wiring that affect electrical safety?

Aluminium wiring has higher thermal expansion compared to copper, causing wires to expand and contract more with temperature changes. This can affect connection integrity. Additionally, aluminium’s conductivity and durability differ from copper, impacting overall electrical safety.

What safety problems are associated with aluminium wiring in homes today?

Loose connections caused by aluminium’s thermal expansion can lead to increased resistance and overheating, raising fire risks. Symptoms include flickering lights, warm or discolored outlets, buzzing sounds, and frequent breaker trips. Homes wired with pre-1972 aluminium are about 55 times more likely to have fire-hazardous connections than those with copper wiring.

What additional issues do homeowners face with aluminium wiring besides fire hazards?

Corrosion at connection points worsens electrical contact quality over time. There are also device compatibility problems when using switches or outlets designed only for copper wiring. These issues can impact home resale value and cause challenges with insurance coverage due to perceived fire risks.

How can homeowners maintain and inspect homes with aluminium wiring?

Regular inspections by certified electricians experienced with aluminium wiring are essential. Maintenance tasks include checking outlet temperatures and performing visual inspections to identify early signs of problems. Permanent solutions involve rewiring with copper wire or using special connectors like COPALUM for safe pigtail connections between copper and aluminium wires.

Why is it important to hire professional electrical services for managing aluminium wiring risks?

Certified experts with experience in handling aluminium wiring safely can provide thorough inspections, upgrades (such as switchboard replacements), repairs, and maintenance tailored for older wiring systems. This expertise helps protect property and loved ones from potential electrical hazards associated with aluminium wiring.