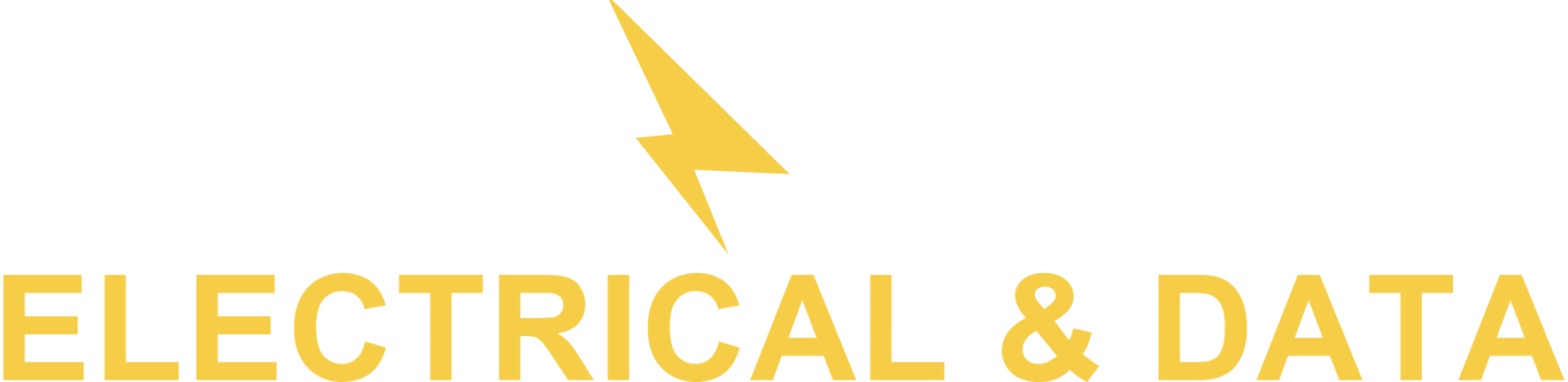

How Three-Phase Power Actually Works in a Small Workshop

Three-phase power is a game-changer for small workshops looking to operate efficiently and safely. Unlike standard single-phase wiring, three-phase power delivers electricity through three alternating currents, creating a more stable and reliable flow of energy. This system is common in industrial environments but is increasingly relevant to smaller operations as machinery becomes more sophisticated.

Understanding how three-phase power actually works in a small workshop can unlock significant benefits:

- Consistent energy delivery reduces equipment wear and minimizes voltage drops.

- Larger motors and advanced tools run smoother, supporting everything from woodworking saws to metal lathes.

- Improved efficiency means less downtime and lower maintenance costs.

Recognizing these advantages makes it easier to decide if upgrading your workshop’s electrical system is worth the investment. A solid grasp of three-phase power puts you in control, allowing you to choose equipment and layouts that boost productivity and safety. If you’re considering this upgrade, don’t hesitate to contact us for expert advice and assistance.

Understanding Three-Phase Power

Three-phase power is a type of alternating current (AC) electrical system used commonly in industrial and commercial settings. Unlike single-phase power, which uses a single sinusoidal waveform, three-phase power consists of three voltage waves that are offset by 120 degrees from each other. This offset creates a more stable and consistent delivery of power.

Comparison to Single-Phase Power

When comparing three-phase power to single-phase power, several key differences emerge:

Single-Phase Power:

- Utilizes one alternating voltage wave.

- Commonly used in residential settings.

- Suitable for lower power requirements.

- Can experience dips and peaks in power delivery.

Three-Phase Power:

- Uses three alternating voltage waves, each phase separated by 120 degrees.

- Typically employed in industrial and commercial environments.

- Capable of handling higher power demands.

- Provides smoother and more constant power delivery.

Benefits of Balanced Power Delivery

The primary advantage of three-phase power lies in its balanced power delivery. The three separate phases ensure that the total power load is evenly distributed, leading to:

- Improved Efficiency: Equipment operates more efficiently due to consistent power flow.

- Reduced Wear: Motors and other machinery experience less stress, extending their lifespan.

- Enhanced Performance: Machines run smoother with fewer interruptions or fluctuations.

This balanced approach minimizes the risk of overloading any single phase, ensuring a safer and more reliable electrical system suitable for demanding applications within small workshops.

Applications in Small Workshops

Three-phase power is particularly advantageous for running heavy machinery and motors efficiently. In a small workshop, this can translate to significant improvements in performance and energy consumption.

Efficient Operation of Larger Motors and Equipment:

- Heavy Machinery: Tools such as lathes, milling machines, and CNC routers benefit from three-phase power, which provides a more consistent and reliable source of energy.

- Motors: Three-phase motors operate more smoothly compared to single-phase motors, reducing wear and tear on the equipment and extending its lifespan.

- Equipment: Devices like air compressors and large saws require substantial power that three-phase systems can deliver without fluctuating or overheating.

Types of Machinery Suitable for Three-Phase Power:

- Industrial-grade woodworking tools

- Metalworking machines

- HVAC systems

- High-capacity welders

Comparison Between Single-Phase and Three-Phase Motors:

| Feature | Single-Phase Motors | Three-Phase Motors |

|---|---|---|

| Performance | Often experience pulsations in torque output, leading to less efficient operation | Provide steady torque output, enhancing overall efficiency |

| Durability | Tend to have shorter lifespan due to uneven power delivery | Generally last longer because of balanced power distribution |

| Efficiency | Less efficient for high-power applications due to reliance on a single alternating current wave | More efficient as it utilizes multiple waves, distributing load evenly |

Incorporating three-phase power into your small workshop can significantly improve the functionality of your machinery, resulting in smoother operations and better productivity. For instance, the transition from single-phase to three-phase power could be a game-changer for many small workshop owners.

Bringing Three-Phase Power to a Small Workshop

Getting three-phase power into a small workshop involves several key considerations, from utility costs to infrastructure upgrades. Understanding how three-phase power actually works in a small workshop starts with the source: the local utility. Extending three-phase service directly from the street can be expensive. Utility costs often include not only installation fees but also ongoing demand charges that can impact your monthly bills.

Exploring Alternatives: Phase Converters

Many small shop owners look for alternatives before committing to direct utility extension. Phase converters offer a practical solution, allowing you to run three-phase equipment using existing single-phase power:

- Rotary phase converters generate a third phase using an idler motor, suitable for running multiple machines.

- Static phase converters provide a cost-effective option for starting motors, though they may not deliver full performance under load.

- Digital phase converters use electronic controls for precise and efficient phase balancing, ideal for sensitive or high-value equipment.

Each option has its own installation requirements and price points. Comparing these against direct utility extension is essential when planning your setup.

Upgrading Infrastructure: Breaker Panels

Infrastructure upgrades don’t stop at the converter or utility connection. Three-phase systems require dedicated breaker panels designed to handle increased current and distribute balanced loads safely. These panels are different from standard single-phase panels, offering:

- Separate slots for each phase

- Enhanced protection through specialized circuit breakers

- Proper grounding and bonding to comply with Australian electrical standards

Protek Electrical and Data often recommends professional evaluation of your workshop’s wiring, load calculations, and panel placement. Safe installation ensures reliability and minimizes downtime during high-demand operations. Upgrading breaker panels also gives you flexibility for future expansion as your equipment needs grow.

Integrating three-phase power into your workshop opens up new possibilities for machinery and efficiency—but only if the supporting infrastructure is thoughtfully planned and expertly installed.

Enhancing Performance with Three-Phase Power

Variable Frequency Drives (VFDs) play a crucial role in maximizing the performance of three-phase motors. VFDs allow for precise speed control and significant improvements in motor performance. By adjusting the frequency and voltage supplied to the motor, VFDs enable smooth acceleration and deceleration, reducing mechanical stress and wear on equipment. This results in not only enhanced efficiency but also prolonged lifespan of the machinery.

Benefits of using VFDs with three-phase motors include:

- Energy Savings: VFDs adjust the motor speed to match the load requirements, which can lead to considerable energy savings.

- Improved Process Control: With precise speed regulation, you can achieve better control over your workshop processes.

- Reduced Maintenance: Lower mechanical stress means fewer breakdowns and maintenance issues.

Investing in three-phase motors also has implications for resale value and durability. Three-phase motors are typically more robust and reliable compared to their single-phase counterparts. This increased reliability translates into higher resale value if you decide to upgrade or sell your equipment in the future.

Key considerations when evaluating resale value and durability:

- Longevity: Three-phase motors tend to have a longer operational life due to their balanced power delivery.

- Market Demand: Industrial-grade equipment designed for three-phase systems is often in higher demand, ensuring better resale opportunities.

- Durability: These motors are built to withstand harsh industrial environments, making them a solid long-term investment for any small workshop.

By integrating VFDs and opting for durable three-phase motors, small workshop owners can significantly enhance their operational efficiency and ensure a higher return on investment through increased productivity and equipment longevity.

Considerations for Small Workshop Owners

When deciding whether to implement three-phase power in your small workshop, a critical factor is weighing the installation costs against the long-term operational benefits. Initial investments can be significant, particularly if you need to extend three-phase service from the utility company. However, these upfront expenses often translate into lower energy costs and improved efficiency over time.

Key Points to Consider:

Installation Costs:

- Extending three-phase service from the utility provider.

- Upgrading electrical infrastructure, including breaker panels and wiring.

- Purchasing three-phase equipment and machinery.

Operational Benefits:

- Energy Efficiency: Three-phase motors consume less power than single-phase motors for the same output, leading to reduced electricity bills. Recent studies have shown that implementing three-phase power can significantly reduce energy consumption in various applications.

- Improved Performance: Three-phase systems provide smoother and more reliable power delivery, which enhances the performance of heavy-duty equipment.

- Durability: Three-phase motors often have a longer lifespan due to balanced power distribution, resulting in fewer mechanical failures.

Advantages of Industrial-Grade Equipment:

Using industrial-grade equipment designed for three-phase systems offers several advantages:

- Higher Resale Value: Equipment that operates on three-phase power typically retains its value better due to its reliability and efficiency.

- Greater Selection: There is a wider variety of industrial-grade machinery available for three-phase systems, providing more options for specialized tasks.

- Longevity: Three-phase equipment generally experiences less wear and tear, increasing its operational life and reducing maintenance needs.

Evaluating these factors carefully will help you make an informed decision about integrating three-phase power into your small workshop.

Conclusion

Adopting three-phase power systems in small workshops enhances operational efficiency and productivity. By providing balanced power delivery, it optimizes the performance of large machinery and motors. Exploring tooling options designed for three-phase systems opens up possibilities for more advanced and reliable equipment. Understanding how three-phase power actually works in a small workshop empowers owners to make informed decisions that lead to long-term benefits.

FAQs (Frequently Asked Questions)

What is three-phase power and how does it work in a small workshop?

Three-phase power is an alternating current system that uses three voltage waves offset in phase to deliver balanced and continuous power. In small workshops, it enables efficient operation of heavy machinery by providing consistent and reliable electrical supply compared to single-phase power.

What are the benefits of using three-phase power over single-phase power in small workshops?

Three-phase power offers balanced power delivery, which reduces electrical stress on equipment, improves efficiency, and supports larger motors and machinery. This results in smoother operation, increased durability of tools, and potential energy savings compared to single-phase systems.

How can small workshops bring three-phase power into their facility?

Small workshops can extend three-phase service by working with utility providers or use alternatives like phase converters to adapt single-phase supply. Implementation requires proper infrastructure such as breaker panels designed for three-phase systems and consideration of associated costs.

What types of machinery in small workshops benefit most from three-phase power?

Heavy machinery, industrial-grade motors, and equipment that demand higher power loads operate more efficiently with three-phase power. This includes CNC machines, large compressors, and other tools designed specifically for industrial applications requiring stable and robust electrical input.

How do variable frequency drives (VFDs) enhance performance when used with three-phase motors?

VFDs allow precise speed control of three-phase motors, improving operational flexibility, energy efficiency, and reducing mechanical stress. This leads to better performance, longer motor life, and potential cost savings in maintenance and energy consumption.

Is investing in three-phase power cost-effective for small workshop owners?

While installation costs for three-phase power can be higher initially due to infrastructure upgrades or equipment purchase, the long-term operational benefits such as improved efficiency, enhanced tool performance, increased resale value of motors, and reduced downtime make it a cost-effective investment for many small workshop owners.