How Electricians Test for Faulty Wiring Without Tearing Down Walls

Faulty wiring poses a significant risk to both property and personal safety, yet diagnosing electrical issues often brings to mind images of torn-down walls and disrupted homes. Traditional inspection methods can be invasive, costly, and time-consuming, sometimes involving unnecessary demolition just to locate a single fault. Modern electricians have transformed this process by adopting non-invasive electrical testing techniques that pinpoint wiring issues without extensive damage.

Today’s professionals rely on advanced tools and systematic processes to deliver accurate faulty wiring detection while preserving your property’s integrity. How electricians test for faulty wiring without tearing down walls is no longer a mystery—it’s a science driven by innovation and expertise.

In this article, you’ll discover:

- The risks associated with faulty wiring

- Common non-destructive testing methods used by certified electricians

- Real-world examples of successful non-invasive diagnosis

- Practical reasons to choose experienced professionals for your next electrical inspection

Understanding Faulty Wiring and Its Risks

Faulty wiring refers to electrical systems that are compromised, unsafe, or no longer performing as intended. Common causes include:

- Wear and Tear: Over time, insulation can degrade, exposing wires and increasing the risk of shorts.

- Physical Damage: Accidental punctures from nails or screws, rodents chewing through cables, and impacts during renovations all contribute to compromised wiring.

- Loose Connections: Improperly tightened terminals or aging connectors create unstable circuits that may overheat.

Recognizing faulty wiring risks is essential for anyone concerned about electrical safety. When wiring issues develop, the dangers multiply quickly:

- Fire Hazards: Damaged or overheating wires are a leading cause of residential and commercial fires. Even a small arc can ignite insulation or nearby materials.

- Power Outages: Sudden loss of power in part or all of a building can point directly to underlying wiring faults.

- Electric Shock: Exposed conductors or improper grounding put occupants at risk of serious injury.

Ignoring these problems allows minor defects to become major threats. Timely detection and repair play a critical role in preventing accidents, especially in environments with high occupancy or sensitive equipment. Whether in homes, offices, or industrial spaces, addressing wiring issues promptly maintains property value and safeguards lives.

Electricians prioritizing early intervention ensure not only compliance with safety codes but also peace of mind for property owners—laying the groundwork for effective non-invasive testing methods.

Non-Invasive Electrical Testing Methods Used by Electricians

1. Visual Inspection at Accessible Points

Electricians often start their assessment by performing a visual inspection of accessible areas such as outlets, switches, and junction boxes. This initial step is crucial in identifying any immediate signs of faulty wiring without causing any damage to the walls.

During this inspection, electricians look for:

- Burnt components: Indications of overheating or short circuits can be seen in burnt or scorched wiring and components.

- Loose wires: Wires that are not securely connected can cause intermittent power issues and pose significant safety hazards.

- Discoloration: This can indicate heat damage or corrosion, signaling potential problems with the connections.

By carefully examining these accessible points, electricians can gather valuable information about the overall condition of the electrical system. This method helps to pinpoint areas that may require further investigation using more advanced tools.

2. Specialized Electrical Testing Tools for Non-Invasive Diagnosis

Electricians use several specialized electrical testing tools to diagnose wiring issues without tearing down walls:

-

Non-contact voltage testers: These devices detect the presence of voltage from outside the wires, allowing electricians to safely identify live circuits without direct contact.

-

Voltmeters: By measuring voltage levels between wires, voltmeters help identify abnormalities that may indicate faulty connections or other issues.

3. Circuit Testers and Their Role in Quick Fault Identification Without Opening Walls

Circuit testers play a key role in quickly checking outlet functionality and circuit integrity. They provide a straightforward way to determine if an outlet is working correctly or if there are issues within the circuit that need addressing.

4. Systematic Troubleshooting Process That Minimizes Invasive Procedures During Fault Detection

Electricians follow a step-by-step approach when using non-invasive methods to isolate faults within a circuit. This systematic process minimizes invasive procedures and ensures efficient fault detection:

- Initial visual inspection at accessible points.

- Use of specialized tools like non-contact voltage testers and voltmeters.

- Employing circuit testers to check outlet functionality.

- Analyzing collected data to identify potential problem areas.

By adhering to this structured process, electricians can effectively diagnose and address faulty wiring issues without unnecessary wall demolition, ensuring both safety and minimal disruption for homeowners and businesses alike.

2. Specialized Electrical Testing Tools for Non-Invasive Diagnosis

Electricians use non-invasive electrical testing methods to find faulty wiring without having to tear down walls. These tools and techniques help them diagnose problems quickly while causing minimal disruption to your property.

Key tools used by electricians in this approach include:

-

Non-Contact Voltage Testers: These devices are essential for safely detecting the presence of voltage from outside the wires. By simply holding the tester near a wire or outlet, electricians can determine if there is live electricity running through it. This immediate feedback helps identify potential problem areas without any need for physical contact or wall demolition.

-

Voltmeters: Voltmeters play a crucial role in measuring voltage levels between wires. By checking the voltage, electricians can spot abnormalities that might indicate faulty connections or other issues. For example, if the voltmeter shows an unexpected reading, it could signal a problem that needs further investigation.

These specialized electrical testing tools ensure a systematic troubleshooting process without wall demolition, making it possible to maintain the integrity of your property while addressing electrical concerns effectively. If you’re experiencing electrical issues in your property, don’t hesitate to contact us for professional assistance.

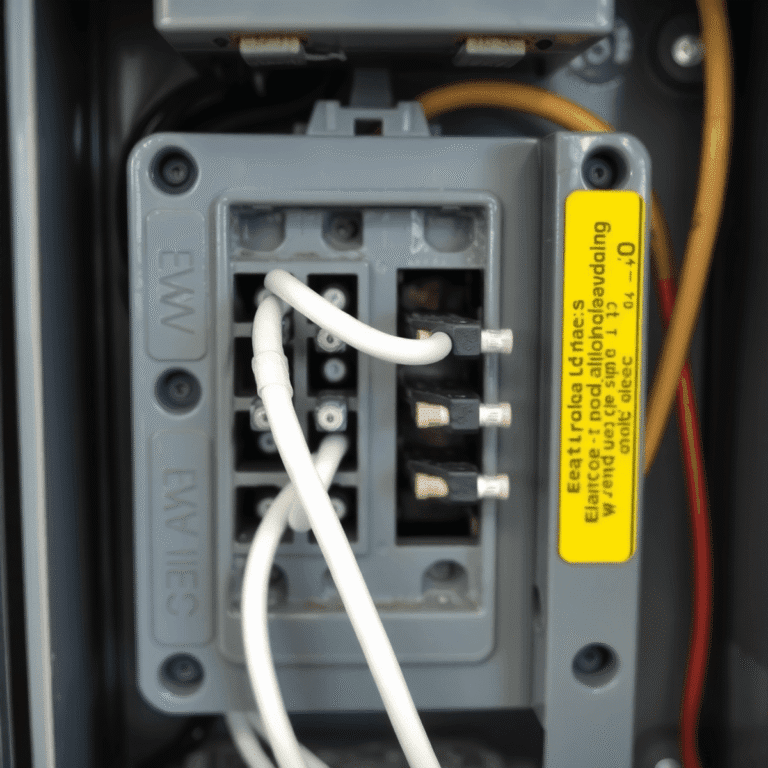

3. Circuit Testers: Quick Fault Identification Without Opening Walls

Circuit testers are essential tools used by professional electricians for non-invasive electrical testing. These specialized devices allow for quick checks of outlet functionality and circuit integrity, eliminating the need to open walls or disrupt finishes.

How Electricians Use Circuit Testers:

- Outlet Inspection: Plug-in circuit testers instantly reveal wiring errors such as open grounds, reversed polarity, or missing neutrals at outlets. The device’s indicator lights provide a clear readout, allowing you to spot issues at a glance.

- Junction Box Check: For junction boxes, electricians use these testers to confirm live power and correct wiring configurations. This helps identify problematic connections that might exist behind switch plates or cover panels.

- Systematic Troubleshooting Process Without Wall Demolition: By methodically testing each outlet or accessible junction within a circuit, faults can be isolated to specific areas. Electricians often combine this with visual inspection electrical wiring techniques, narrowing down the suspect portion of wiring without unnecessary demolition.

The result is a fast, accurate method for pinpointing faults—such as broken wires or loose terminals—hidden within walls. This approach minimizes guesswork and unnecessary repairs, aligning perfectly with modern best practices on how electricians test for faulty wiring without tearing down walls. Circuit testers are essential not only for initial diagnostics but also for confirming repairs have addressed the root problem before closing up any access points.

4. Systematic Troubleshooting Process That Minimizes Invasive Procedures During Fault Detection

Non-invasive electrical testing methods rely heavily on a structured, logical approach to pinpoint faults with minimal disruption. Electricians follow a systematic troubleshooting process that combines visual inspection electrical wiring, outlet inspection, and junction box check with the use of specialized electrical testing tools for non-invasive diagnosis. This method is designed to isolate problems efficiently—without resorting to wall demolition.

Step-by-Step Approach Used by Professionals:

-

Initial Assessment

- Begin with a walkthrough and consultation to gather details about symptoms or previous issues.

- Identify affected areas, noting any patterns in outages or malfunctions.

-

Visual Inspection

- Inspect accessible outlets, switches, and junction boxes for visible signs of wear, discoloration, or loose connections.

- Check for burnt marks or unusual odors—often early indicators of faulty wiring.

-

Targeted Use of Non-Invasive Tools

- Deploy non-contact voltage testers and voltmeters across outlets and switches, confirming the presence or absence of voltage without touching bare wires.

- Utilize circuit testers at various points to verify circuit integrity.

-

Systematic Isolation

- Methodically test individual sections of the circuit in sequence, starting from the main panel toward branch circuits.

- Document responses at each point to narrow down the fault’s location.

-

Analysis and Diagnosis

- Cross-reference tool readings with observations from inspections.

- Formulate a diagnosis based on data collected, allowing targeted repairs without unnecessary wall damage.

This systematic electrical troubleshooting process ensures safety and efficiency while answering the pressing question: How Electricians Test for Faulty Wiring Without Tearing Down Walls. Certified professionals like those at Protek Electrical and Data prioritize these non-invasive approaches, ensuring effective results with minimal disruption.

Case Study Example: Diagnosing Faulty Wiring in a Melbourne Home Using Non-Invasive Techniques

Here’s an example of how Protek Electrical and Data successfully diagnosed faulty wiring in a Melbourne home using non-invasive techniques.

The Problem

A homeowner in Melbourne noticed flickering lights and occasional power outages in their living room. Worried about potential faulty wiring, they reached out to Protek for help.

The Process

When the certified professionals from Protek arrived, they began with a visual inspection at accessible points like outlets and switches. They looked for any signs of damage, discoloration, or burnt components that could indicate a problem. However, they didn’t find any obvious issues.

Using Specialized Tools

Since the visual inspection didn’t reveal anything, the electricians decided to use specialized tools for a non-invasive diagnosis:

- Non-contact voltage testers: These tools allow them to detect the presence of voltage without directly touching the wires, ensuring safety during the process.

- Voltmeters: By measuring voltage levels between wires, they can identify any abnormalities that might signal faulty connections.

Checking Outlet Functionality

After using the non-invasive tools, the electricians employed circuit testers to quickly check outlet functionality. This revealed an inconsistency in one of the circuits.

The Solution

Using their systematic troubleshooting process, the electricians were able to isolate the fault within the circuit without having to tear down any walls. They traced the issue back to a loose connection within a junction box hidden behind a drywall panel. By accessing this point alone, they were able to resolve the problem swiftly with minimal disruption.

The Outcome

This case study demonstrates how Protek’s expertise allows them to maintain high safety standards while minimizing damage to homes during repairs. Their proficiency with non-invasive techniques ensures efficient fault diagnosis and repair, providing peace of mind for homeowners concerned about electrical safety.

Benefits of Hiring Experienced Electricians Who Use Modern Fault Detection Techniques Without Tearing Down Walls

Choosing licensed electricians like Protek Electrical and Data who use advanced diagnostic methods has many benefits:

- Less Disruption: Non-invasive electrical testing methods ensure that your walls remain intact, preventing the need for costly and time-consuming repairs.

- Safety Assurance: Certified professionals use modern tools and techniques to accurately diagnose issues, reducing the risk of electrical hazards such as fires or shocks.

- Efficient Problem-Solving: Advanced diagnostic tools allow for quick and precise identification of faults, ensuring that issues are addressed promptly and effectively.

- Cost Savings: By avoiding unnecessary wall demolition, homeowners and businesses can save on both labor and material costs associated with traditional inspection methods.

- Preservation of Property Aesthetics: Non-invasive techniques help maintain the integrity and appearance of your property, avoiding unsightly damage.

Choosing experienced electricians who use these modern fault detection techniques ensures high-quality service while protecting your property.

Conclusion

Electrical problems won’t fix themselves. Ignoring the signs puts your property and safety in danger. It’s important to get licensed professionals involved right away. Certified electricians have the tools and knowledge to find problems using non-invasive testing methods, like visual inspections, non-contact voltage testers, voltmeters, and circuit testers—avoiding the need to tear down walls unnecessarily.

If you see lights flickering, breakers tripping, or suspect faulty wiring, contact a reliable electrician who is skilled in modern diagnostic techniques. Acting quickly and getting expert help will safeguard your home or business from expensive damage and disruptions.

Summary of faulty wiring testing methods: Modern electricians focus on accuracy and minimizing disruption—this is how electricians test for faulty wiring without tearing down walls.

FAQs (Frequently Asked Questions)

What are the common risks associated with faulty wiring in homes and commercial properties?

Faulty wiring can lead to serious dangers including fire hazards, power outages, and electrical shock risks. These issues often arise from wear, damage, or loose connections, making timely detection and repair essential for safety.

How do electricians test for faulty wiring without tearing down walls?

Electricians use non-invasive electrical testing methods that include visual inspections at accessible points like outlets and junction boxes, specialized tools such as non-contact voltage testers and voltmeters, circuit testers for quick fault identification, and a systematic troubleshooting process that minimizes the need for wall demolition.

What specialized tools do electricians use to detect faulty wiring non-invasively?

Key tools include non-contact voltage testers that safely detect voltage presence without direct contact, voltmeters to measure voltage levels between wires indicating abnormalities, and circuit testers to check outlet functionality and circuit integrity swiftly without opening walls.

Why is visual inspection important in identifying faulty wiring?

Visual inspection allows electricians to assess accessible areas such as outlets, switches, and junction boxes for signs of faulty wiring like burnt components, loose wires, or discoloration. This initial step helps pinpoint potential issues without invasive procedures.

Can you explain the systematic troubleshooting process electricians follow during non-invasive fault detection?

Electricians follow a step-by-step approach starting with visual inspections followed by using specialized testing tools to isolate faults within circuits. This methodical process ensures accurate diagnosis while minimizing invasive actions like wall demolition.

What are the benefits of hiring experienced electricians who use modern non-invasive fault detection techniques?

Licensed electricians employing advanced diagnostic methods provide safer, more efficient fault detection with minimal disruption. They ensure compliance with safety standards while reducing repair time and costs by avoiding unnecessary wall damage.